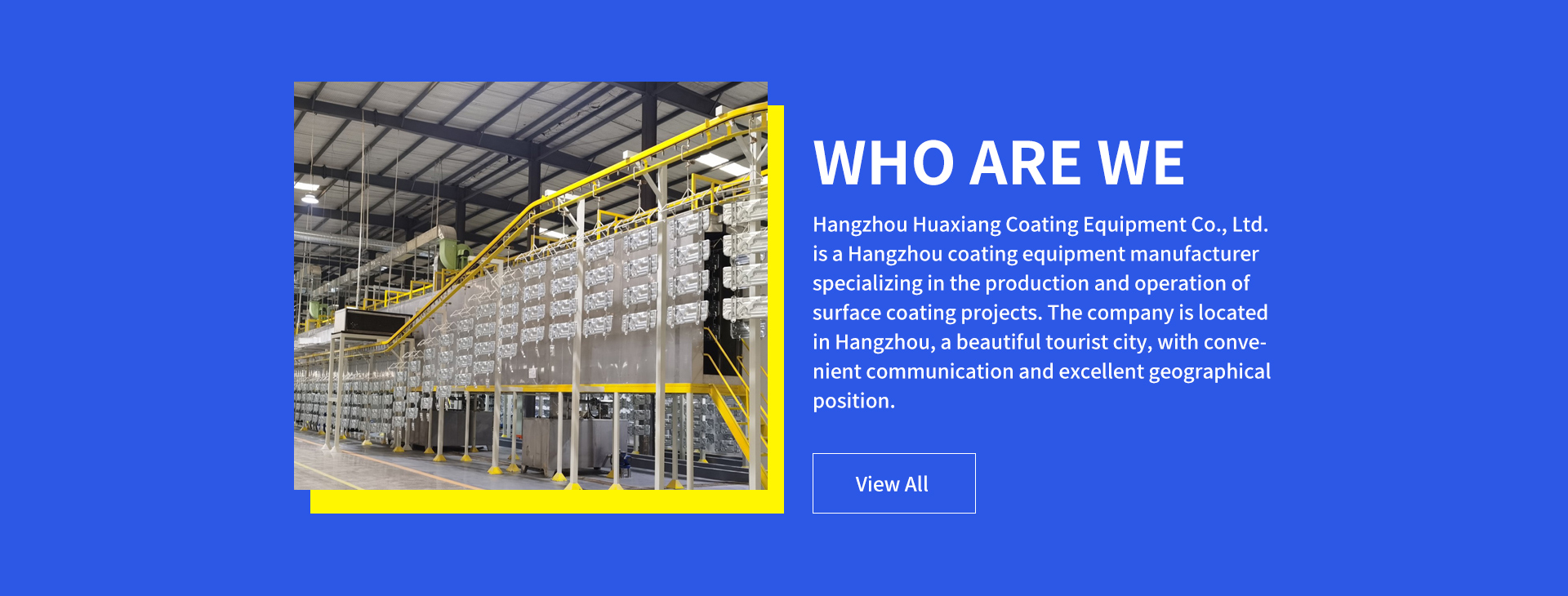

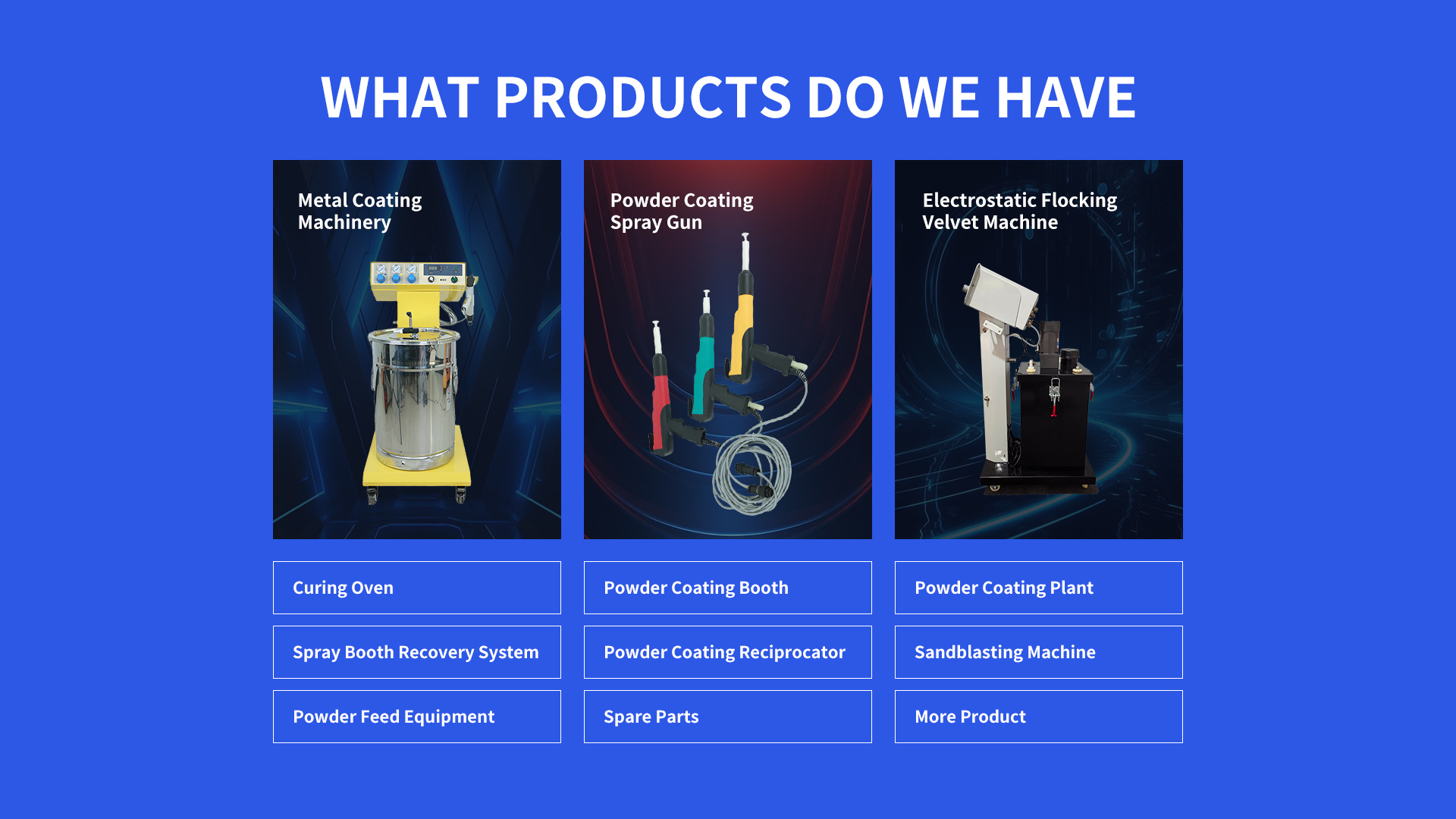

Introduction to Electrostatic Powder Coating Machines

Electrostatic Powder Coating Machines are innovative tools that apply dry, solvent-free coatings to metal surfaces using electrostatic charges. These machines attract and bond powder particles to grounded objects, creating a uniform, durable finish resistant to corrosion, scratches, and UV damage. Ideal for industries like automotive, aerospace, and furniture manufacturing, they eliminate harmful VOC emissions, reduce material waste, and lower operational costs. With options ranging from manual units for small workshops to automated industrial systems, electrostatic powder coating machines ensure high-quality results while supporting eco-friendly practices.

1. Electrostatic Powder Coating Machine Components and Structure

An Electrostatic Powder Coating Machine includes three core components:

Electrostatic Powder Coating Machine Spray Gun: Generates a high-voltage charge (30–100 kV) to ionize and propel powder particles.

Powder Feed System: Comprises a hopper, fluidizing bed, and pump to deliver consistent powder flow.

Curing Oven: Heats coated parts (160–200°C) to melt and cure the powder into a smooth layer.

Advanced models feature powder recovery systems to recycle overspray, digital controllers for precise temperature adjustments, and conveyor belts for automated workflows. These components ensure electrostatic powder coating machine efficiency and minimal waste.

2. Applications of Electrostatic Powder Coating Machines

These Electrostatic Powder Coating Machines are widely used for:

Automotive Parts: Coating wheels, engine components, and chassis for rust resistance.

Home Appliances: Applying scratch-resistant finishes to refrigerators, ovens, and washing machines.

Architectural Metalwork: Protecting railings, window frames, and steel beams from weathering.

Niche uses include coating medical equipment, agricultural machinery, and consumer electronics. Their ability to handle complex geometries makes them ideal for intricate parts like bicycle frames or industrial valves.

3. Electrostatic Powder Coating Machine Design Considerations

Key design Electrostatic Powder Coating Machine factors include:

Safety: Explosion-proof components, proper grounding, and ventilation to manage flammable powders.

Energy Efficiency: Insulated ovens and heat recovery systems to reduce power consumption.

Ergonomics: Lightweight spray guns and adjustable settings to minimize operator fatigue.

Maintenance: Easy-access panels for cleaning and replacing filters. Prioritizing these elements ensures electrostatic powder coating machine durability and compliance with industry standards.

4. How to Choose an Electrostatic Powder Coating Machine

Consider these Electrostatic Powder Coating Machine factors:

Production Scale: Manual machines (under 5,000)suitlow−volumetasks;automatedsystems(15,000+) handle bulk orders.

Material Compatibility: Ensure the machine supports metals like steel, aluminum, or pre-treated substrates.

Certifications: Look for CE, ISO, or UL marks for safety assurance.

Budget: Compare electrostatic powder coating machine prices, including energy use and maintenance costs. Test samples to verify coating quality before purchase.

5. Electrostatic Powder Coating Machine Q&A

Q: Can these machines coat non-conductive materials?

A: No, electrostatic coating requires conductive surfaces. Pre-treatment with conductive primers may enable coatings on plastics or wood.

Q: How to prevent uneven powder distribution?

A: Maintain proper gun distance (6–12 inches), ensure grounding, and check electrostatic powder coating gun calibration regularly.

Q: Are these machines eco-friendly?

A: Yes, they produce zero VOCs and recycle 95%+ of unused powder, aligning with electrostatic coating sustainability goals.

Q: What safety gear is essential?

A: Use respirators, anti-static gloves, and protective goggles to meet electrostatic powder coating safety protocols.

Q: How long does curing take?

A: Typically 10–20 minutes, depending on oven temperature and coating thickness.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com